Is it Time to Mix it Up? How Combining Single-Use and Multi-Use Burs Can Increase Efficiency April 18, 2023

Learn why Leora Walter, DDS, prefers to use a combination of single-use and multi-use burs to increase efficiency.

Read More

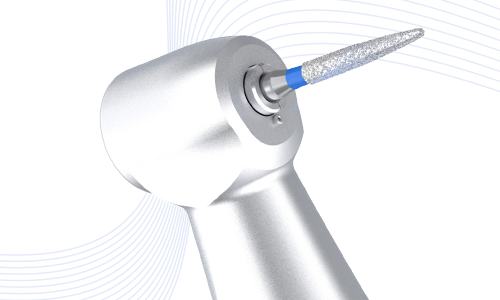

Your Guide to Dental Bur Shank SizesApril 6, 2023

Learn about the specialty-sized dental shanks that can fit any sized mouth.

Read More

What’s The ReFlex® Motion ?March 21, 2023

Learn about the patented movement that is exclusively available with the Procodile Q™ file on the EndoPilot.

Read More

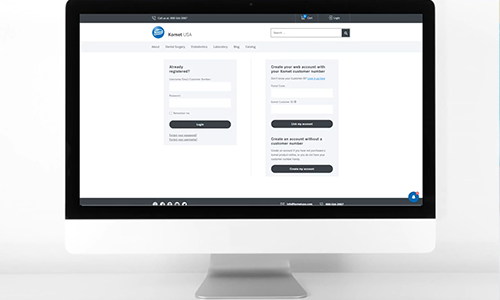

How to Create an Online AccountMarch 9, 2023

It's easy to set up an online account with us, and when you get exclusive discounts, why wouldn't you?!

Read More

Komet – 100 Years of Preparation for TomorrowFebruary 21, 2023

Komet’s 100th Anniversary celebrates a century of dedication to innovating the standards of dentistry

Read More

Complete Solutions to Finesse Your Finishing ProceduresFebruary 9, 2023

Finishing is critical to a beautiful result. The burs and techniques that you use will determine the outcome of the procedure. Luckily for you, Komet has kits that contain any and every instrument you need to get the job done right.

Read More

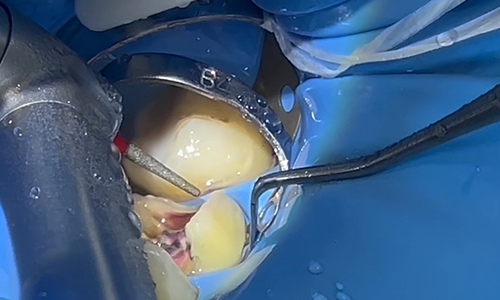

Everything You Should Know About the CeraBur®January 24, 2023

Learn everything about the ceramic round bur that can revolutionize your cavity preparation procedures and help retain healthy tooth structure.

Read More

A Dentist's History with Single-Use BursJanuary 3, 2023

Dr. Christian Yaste recounts his history with single-use burs and the innovations that Komet USA brought to the single-use market.

Read More

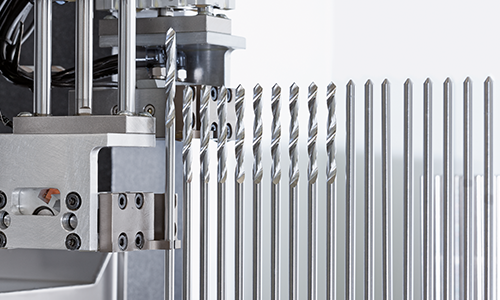

Komet USA's Carbide Manufacturing ProcessDecember 20, 2022

When you grab a fresh carbide bur, do you ever stop to think how it was created? You probably should.

Read More